Fill the form to download the product brochure

Achieving a high Overall Equipment Effectiveness (OEE) is significantly challenging,

especially under very harsh conditions, due to:

Our seals have made a difference for the steel industry for decades, and now, thanks to Tenute’s

know-how, we are heading to innovate the metal industry, here’s how:

Partners rather than customers

Partners rather than customers  Outstanding seal quality

Outstanding seal quality  Our knowledge is knowing-why

Our knowledge is knowing-why  The right design for every application

The right design for every application  Proprietary skills

Proprietary skills  Life span is aligned with the maintenance cycle

Life span is aligned with the maintenance cycle

Extend maintenance

interval

Increase the reliability

of operations

Reduce environmental

impact

These applications operate in corrosive environments that are highly contaminated by scale, sludge, and water. They work at high ambient temperatures with very high loads at very low speeds.

SKF recommended seals: Rotary distributor seals | Radial shaft seals | Hydraulic seals | Machined seals

These applications work in environments severely contaminated by humidity, where space and access are limited. They're exposed to high temperatures and support high peak loads.

SKF recommended seals: Hydraulic seals | Heavy industrial Shaft seals | Speedil-sleeve seals | V-ring seals | Radial shaft seals

These applications work in contaminated environments, under high loads at very low rotating speeds, and are subject to excessive vibrations during blowing.

SKF recommended seals: Converter seals | Speedil-sleeve seals | V-ring seals | Radial shaft seals

These applications operate in heavily contaminated environments, under high loads and low rotating speeds, often facing intense vibrations during blowing.

SKF recommended seals: Speedil-sleeve seals

| V-ring seals

| Radial shaft seals

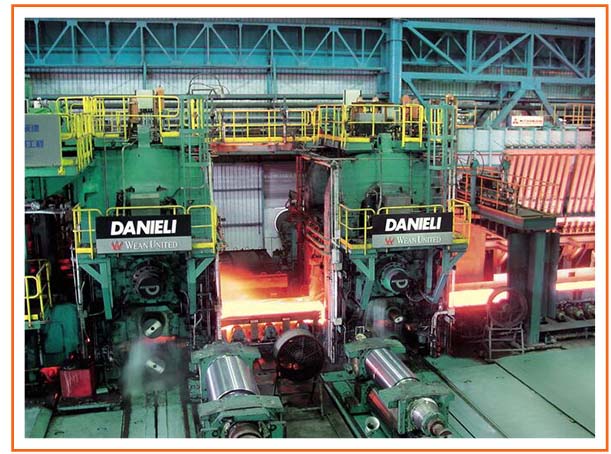

This applications are under pressure to produce more, higher-quality steel. Equipment needs to cope with demands of greater dimensional accuracy, improved surface quality, higher steel grades and output speed.

SKF recommended seals:

O-rings | Hydraulic seals | Speedi-sleeve seals |

HDS | HSS | TR/4/L

This application, operates at speed reaching 125 m/s or more, especially under extreme heat, pressure, and contamination, standard seals often fail prematurely. This challenge is familiar to lead producers of steel bars and wire rods

SKF recommended seals:

TR/8/PTV | V-ring | HMS |

Speedi-sleeve seals

| Machined seals | O-rings