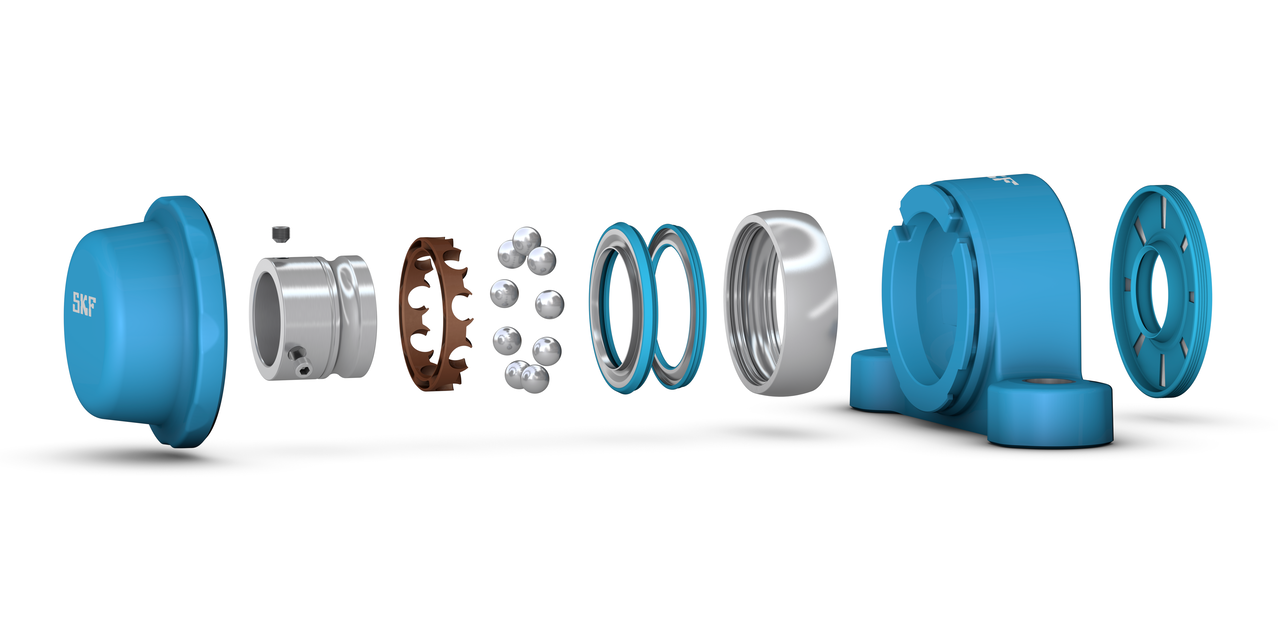

With food recalls on the rise and safety regulations becoming stricter across the globe, proactive food safety programs have become the norm. As a result, companies must incorporate the latest advancements in hygienic design into all of your food processing assets – while also supporting your most critical goals around performance, cost and sustainability. The SKF Food Line ball bearing units – Blue Range have been developed to offer a complete range of hygienic and high-performance bearing unit solutions for the most demanding Food and Beverage environments. Specially developed to help eliminate contaminants and to reduce the spread of bacteria, they provide a solution to many food safety issues. Lubricated for life and designed to withstand frequent washdowns, the new bearing units also solve many of the problems connected with traditional maintenance.

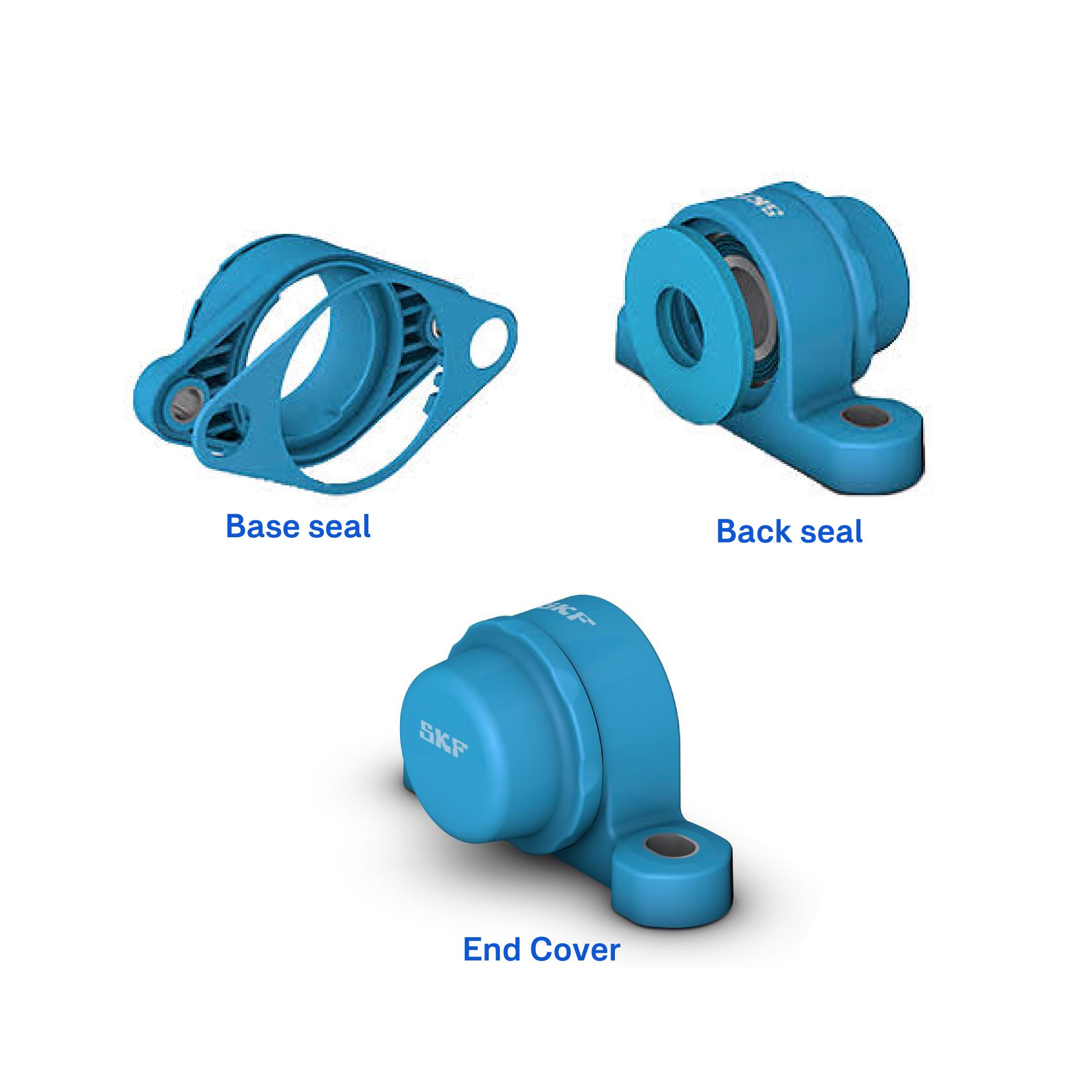

SKF Food Line ball bearing units – Blue Range have been specifically designed from the ground up, component by component, for improved hygiene and compliance with food safety regulations