Reduce unplanned downtime and boost productivity.

Engineered for tough operations with excellent wear resistance.

Improve operational efficiency and reduce premature failures.

Backed by SKF’s superior engineering and Drishti PowerTech’s local support

SKF provides on-site training for mounting, dismounting, and lubrication best practices.

Technical fit solutions for your applications

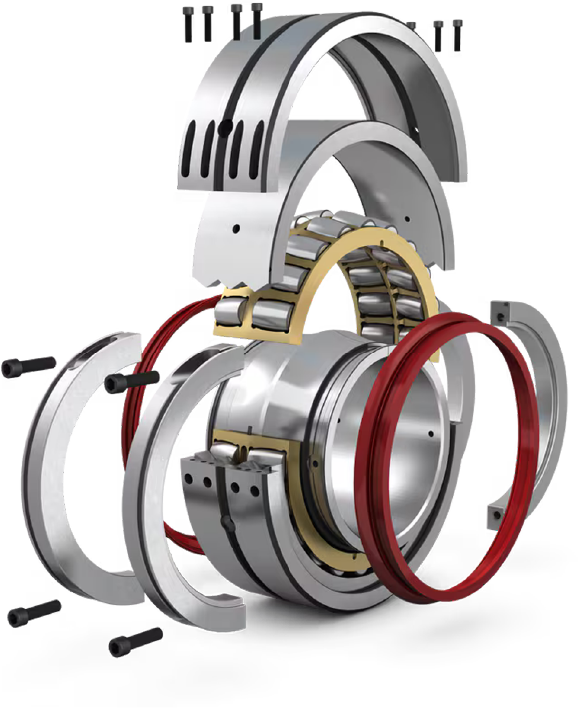

Cooper split spherical roller bearings are engineered for demanding environments where access is limited and downtime is costly. Their split design enables quick installation and easy maintenance, minimizing disruption and maximizing uptime. Ideal for tough conditions, they help reduce total cost of ownership while ensuring reliable performance in the most challenging operations.

Lower MTTR (Mean Time to Repair)

On-site replacement

Longer service life

Sealed for protection

Versatile compatibility

Enhanced safety

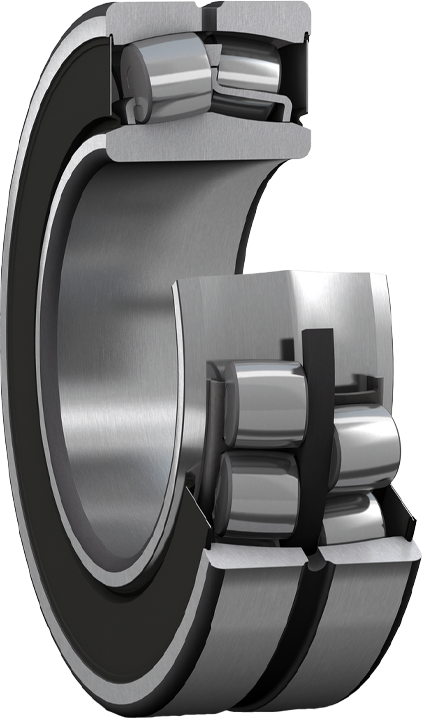

SKF’s Sealed SRBs are engineered to prevent contamination and extend bearing life in

harsh environments. They are ideal for applications like bucket elevators, conveyors,

and feeders, where dust, debris, and moisture threaten operational efficiency.

2x life

Lower maintenance costs

Higher equipment uptime

Maintenance free operations

Lower grease consumption

SKF’s CARB bearings combine the load-carrying capacity of spherical bearings with the axial displacement capability of cylindrical bearings. This reduces friction, minimizes heat generation, and enhances energy efficiency, making them perfect for heavy-duty applications like processed fans, ball mill pinions & crushers.

Mostly designed to implemented at non-drive end of the assembly to enhance the performance.

Bearing float adjustment

Self-aligning capability

Lower friction & heat generation

Higher load-carrying capacity

Extended bearing life

Even load distribution

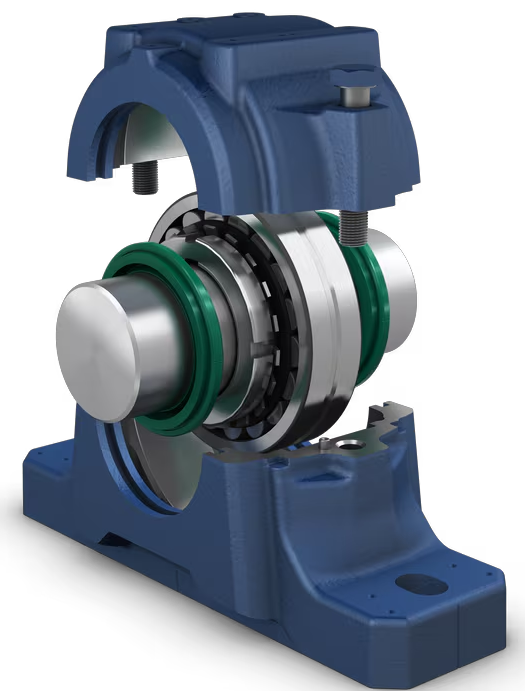

SKF’s Plummer block housing – special tolerance is designed to eliminate rotational looseness and outer ring rotation issues, ensuring a secure bearing fit. This is critical in fan applications for cement plants, where even minor failures can disrupt entire operations.

Reduces bearing failure by preventing outer ring rotation, thus increases reliability

Reduced vibration levels

Optimized for critical applications

Tailored solution

SKF solutions are designed to combat contamination and maintain reliability in harsh environments.

Our training programs ensure proper mounting and dismounting procedures to minimize issues.

SKF’s CMP (Certified Maintenance Partner) services provide real-time condition monitoring to prevent premature failures.

SKF solutions and services work together to improve equipment reliability and extend service life in tough conditions.

Increased uptime & reliability

SKF solutions reduce downtime and boost reliability.

Reduced vibration & temprature levels

Our technology cuts vibrations, boosting stability and extending equipment life.

Excellent wear resistance

SKF's products are built to last, withstanding the toughest conditions.

Strategic partnership

SKF provides smart solutions for construction and mining.

Utilize SKF’s condition monitoring programs to proactively manage equipment health and avoid unexpected failures.

We offer comprehensive training for technicians to enhance skills in mounting, dismounting and lubrication.