The Ultimate Guide to Right Angular Contact Ball Bearings for Precision Engineering

Posted date: 2025-06-18 12:16:48

The selection of appropriate angular contact ball bearings plays a crucial role in maximising operational efficiency and equipment lifespan across engineering projects. These specialised components excel at managing combined loads and find extensive use throughout numerous sectors, from automotive to aerospace industries. Understanding their characteristics and selection criteria is essential for ensuring optimal performance in your specific application. This guide outlines essential considerations for choosing the optimal angular contact ball bearing for your specific requirements.

Understanding Angular Contact Ball Bearings

These specialised bearings feature a distinctive design where the inner and outer ring raceways are offset along the bearing's axis. This configuration enables effective management of both radial and axial loads, making them essential for applications demanding precision, high rotational speeds, and substantial load-bearing capabilities. Their unique construction allows for smoother operation and enhanced stability compared to conventional bearing designs.

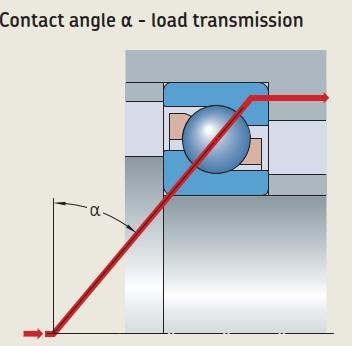

The bearing's contact angle significantly influences its axial load capacity. This angle is measured between two lines: one connecting the ball's contact points with the raceways in the radial plane, and another perpendicular to the bearing axis. Higher contact angles accommodate greater axial loads but may reduce radial load handling capacity. This fundamental concept guides appropriate bearing selection and impacts long-term performance in specific applications. Understanding the relationship between contact angle and load capacity is crucial for optimising bearing performance in your specific application.

Essential Selection Criteria

- Load Requirements Understanding load patterns is fundamental to proper bearing selection:

- Radial vs Axial Loads: Consider the proportion between these loads. Higher contact angles suit substantial axial loads, whilst smaller angles better handle predominantly radial loads. The specific load distribution in your application will determine the optimal contact angle configuration.

- Dynamic and Static Loads: Dynamic loads necessitate consideration of long-term fatigue resistance, whilst static loads require attention to maximum load thresholds to avoid permanent deformation. Regular assessment of loading conditions helps ensure prolonged bearing life and reliable operation.

- Speed Considerations Applications involving high speeds require bearings engineered to minimise friction and heat generation. SKF’s super-precision angular contact ball bearings Precision P4 and P4A deliver outstanding performance in high-velocity environments like turbines and machine tool spindles. The bearing’s ability to maintain stability and precision at elevated speeds is crucial for many modern industrial applications. Proper consideration of speed requirements ensures optimal performance and prevents premature bearing failure.

- Accuracy and Structural Rigidity For applications requiring exceptional precision, such as robotics and CNC equipment, bearings with strict tolerances are essential. SKF offers precision-engineered options that ensure optimal performance in demanding scenarios. The level of precision directly impacts manufacturing quality and equipment reliability. Modern manufacturing processes demand increasingly precise bearing solutions to meet stringent quality requirements.

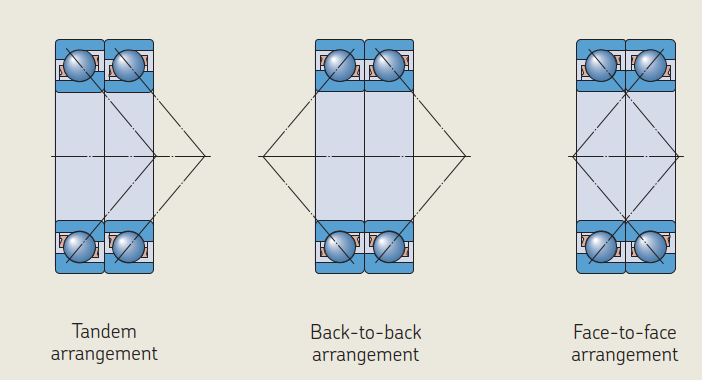

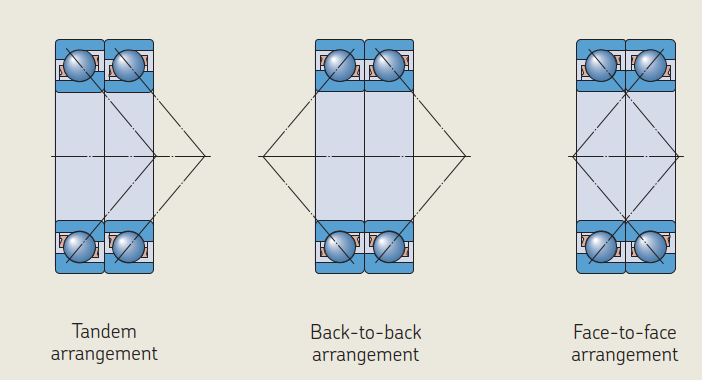

- Bearing Configuration These bearings often operate in pairs or groups to enhance load capacity and manage bi-directional axial loads. The arrangement choice significantly impacts system performance and reliability. Common arrangements include:

- Back-to-Back (DB): Provides enhanced rigidity and manages tilting moments. This configuration excels in applications requiring high stability and precise shaft positioning.

- Face-to-Face (DF): Ideal for applications with minor misalignment issues. This arrangement offers greater flexibility in accommodating shaft deflections.

- Tandem (DT): Enhances unidirectional axial load capacity. Particularly suitable for applications with predominantly axial loads in one direction. The chosen configuration significantly impacts overall system performance and must align with specific application requirements.

- Lubrication Requirements Proper lubrication is vital for reducing friction and preventing overheating. Regular maintenance of lubrication systems ensures optimal bearing performance and longevity. Options include:

- Grease Lubrication: Suited for standard operations with minimal maintenance needs. Modern grease formulations offer extended service life and improved performance.

- Oil Lubrication: Preferred in high-speed or high-temperature scenarios. Continuous oil circulation provides superior cooling and contaminant removal. SKF provides sealed bearings pre-filled with grease, reducing maintenance requirements and ensuring consistent lubrication throughout the bearing’s service life.

- Environmental Factors Operating conditions influence bearing selection and long-term reliability:

- Corrosive Environments: Demand stainless steel construction or protective coatings. Special consideration must be given to seal design and material selection.

- High-Temperature Applications: Require specialised materials and lubricants. Temperature limits affect both bearing materials and lubrication systems.

- Contaminated Environments: Benefit from sealed or shielded designs. Enhanced sealing solutions protect against particulate ingress and ensure extended service life. SKF's Range of Solutions

SKF's Range of Solutions

SKF leads the industry in bearing technology, offering various options designed to meet diverse application requirements:

- Single-Row Variants Ideal for unidirectional axial loads, these bearings suit electric motors and pumps, offering excellent high-speed capabilities. Their versatile design makes them suitable for a wide range of industrial applications.

- Double-Row Options These compact solutions handle bi-directional axial loads, functioning similarly to paired single-row bearings in a back-to-back arrangement. Their space-efficient design reduces overall equipment size while maintaining performance.

- Four-Point Contact ModelsThese space-efficient bearings manage bi-directional axial loads, commonly used in rotating mechanisms. Their unique design provides excellent performance in applications with limited mounting space.

- Super-Precision Series (Precision P4, P4A) Engineered for high-speed, high-precision applications in machine tools and medical equipment. These bearings represent the pinnacle of bearing technology and precision manufacturing.

Key Benefits

- Superior Load Capacity: Optimised design allows for increased ball count, enabling higher load management and improved load distribution across the bearing.

- Precision Engineering: Strict manufacturing controls ensure exceptional dimensional accuracy and consistent performance across all bearing series.

- Robust Construction: Designed for challenging operational environments, reducing maintenance requirements and extending service life in demanding applications.

- Adaptability: The comprehensive range suits diverse industrial applications, offering solutions for virtually any engineering challenge.

Practical Applications

- Machine Tool Spindles: These bearings ensure precise, stable operation in high-speed machining applications, contributing to improved manufacturing quality and productivity.

- Automotive Transmissions: Double-row variants provide compact solutions for combined load management in modern automotive powertrains.

- Industrial Pumping Systems: Single-row bearings excel in managing combined loads at high operational speeds, ensuring reliable pump operation in critical processes.

Final Thoughts

Selecting appropriate angular contact bearings significantly impacts system performance and reliability. Careful consideration of operational requirements, environmental conditions, and precision needs enables informed selection. SKF’s comprehensive range offers solutions. for diverse industrial applications, backed by decades of engineering expertise and continuous innovation.

SKF's E-Marketplace continued innovation and expertise make them a reliable partner for modern engineering challenges. Their product range provides solutions to optimise various engineering applications, ensuring long-term reliability and performance in demanding industrial environments.

Tags:

balls Bearing ,

ball bearing types ,

ball bearing manufacturer ,

bearing pricing ,

Deep Groove Ball Bearing ,

Angular Contact Ball Bearings ,

SKF Ball Bearings ,

Roller Bearing ,

roller bearing types ,

Spherical roller bearings ,

Tapered Bearing ,

Cylindrical Roller Bearing ,

Types Bearings ,

Types of Bearings ,

SKF Bearings ,

Single Row Deep Groove Ball Bearing ,

Skf Deep Groove Ball Bearing ,

Deep Groove Ball Bearing are Used For ,

Deep Groove Ball Bearing Size Chart

Author:

SKF